550A Continuous Rotary Extrusion Line for Copper Alloy Trolley Wire

Basic Info

Model No.: 300-250

Product Description

Product Description 550A Continuous Rotary Extrusion Line for Copper Alloy Trolley Wire

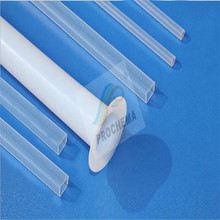

The continuous rotary extrusion line is especially designed for producing copper alloy trolley wires. The continuous extrusion machine, the key component of the production line, adopts the new die cavity featuring modular construction and high temperature resistance so as to extrude copper alloy products with the tensile strength up to 265N/mm 2 . Through deep processing one more time, the tensile strength can reach 650N/mm 2 .

This range of copper alloy trolley wire production line can effectively improve the constitution of extruded copper alloy wires, making the product structure densified and even. Thus, the requirements for high strength and high conductivity can be fully met. Additionally, our continuous rotary extrusion equipment makes use of the new abutment characterized by great strength and exceptional high temperature resistance. For this reason, this continuous rotary extrusion line is capable of manufacturing copper magnesium trolley wire with the magnesium content being 6‰. It is also ideal for extrusion molding of other types of copper alloy wires.

Technical Specifications

Construction

550 Continuous Rotary Extrusion Line for Copper Busbar

The TJ550 continuous rotary extrusion line is designed to form copper busbars with maximum width of 260mm. By exchanging the extrusion die, the copper extrusion equipment can also be applied to produce copper alloy conductors and other types of copper products with sectional area between 380 and 5000mm2. These extruded busbars are regularly found in power distribution cabinets, electrified railway systems, and more.

Our continuous rotary extrusion line adopts copper rod as feedstock. The maximum rod diameter is 22mm. Available with copper rod payoff machine and extruded busbar take-up machine, our range of continuous rotary extrusion machinery has high efficiency, with maximum output up to 2500kg/h. The touch screen design for its electrical control system ensures optimized operation convenience.

Technical Specifications

Configuration of the Copper Busbar Production Line

500 Continuous Rotary Extrusion Line for Copper Busbar

Features The TJ500 continuous rotary extrusion line supports producing not only busbar but also other copper alloy conductors such as the copper bar. The extruded products are extensively used as the contact wire for electrical systems, power distribution cabinets, and electric railways. In addition, the continuous rotary extrusion equipment is also optimum for extrusion of copper alloy contact wires, including copper tin, copper silver and copper magnesium alloy with low magnesium content types.

Adopting Φ22 mm oxygen-free copper rod made via the upward casting process as the feedstock, this series of continuous rotary extrusion line is capable of producing copper busbars and profiled bars with width ranging from 170 to 240mm. The touch screen for the electrical control system ensures easy and convenient operation.

Technical Specifications

Components of the Copper Busbar Forming Machine

400 Continuous Rotary Extrusion Line for Copper Busbar

Features

1. The TJ400 copper busbar continuous rotary extrusion line uses Φ20mm oxygen-free copper rods which can be simply produced using upward casting technique as the feedstock to manufacture high quality oxygen-free copper busbar with a sectional area below 3000mm2.

2. Adopting the innovative online scrapless cutting technique, this range of continuous rotary extrusion machine maximizes the feedstock utilization rate, which helps users cut down production cost.

3. The modular structure of main components and the extrusion die ensures convenient parts replacement, thus minimizing the maintenance cost.

4. The maximum extruded copper product width is up to 170mm, and the average production speed of the continuous rotary extrusion line reaches 1100kg/h.

Applications

This continuous rotary extrusion line is originally designed for copper busbar production. Also, it can be utilized for manufacturing the copper bar, copper rod, and other types of extruded copper products that are widely used in the motors, transformers, and power distribution cabinets.

Technical Specifications

Main Components of the Production Line

350 Continuous Rotary Extrusion Line for Copper Busbar Features

1. Due to continuous extrusion technique, the TJ350 copper busbar continuous rotary extrusion line can complete copper busbar extrusion at one time, without the need for edge trimming, acid pickling, etc. Thus, both production process and production period are shortened.

2. The continuous extrusion equipment won't cause production wastes such as the scrap edge of copper busbar, or the residuals in the extrusion barrel. This ensures high raw material utilization rate, and our first pass yield exceeds 95%.

3. Adopting friction force for feedstock heating, our continuous rotary extrusion line for copper busbars eliminates heating and annealing steps. This makes sure the production process is simplified and environmental friendly as well due to lower energy consumption and lower carbon emission.

4. Continuous rotary extrusion machines support producing products with unlimited length. This, coupled with the automatic take-up unit, makes our copper busbar forming machine highly efficient.

5. When the desired busbar width is less than 100mm, our continuous rotary extrusion line offers average productivity up to 800kg/h.

Applications

TJ350 range of continuous rotary extrusion equipment offers an ideal solution to make copper busbars, and other types of copper products by exchanging the extrusion die. The extruded copper products are widely utilized in electric motors, power distribution cabinets, transformers, etc.

Technical Specifications

Main Components of the Production Line

Contact us if you need more details on Copper Sheet Extrusion Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Copper Bar Extrusion Line、Copper Alloy Trolley Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

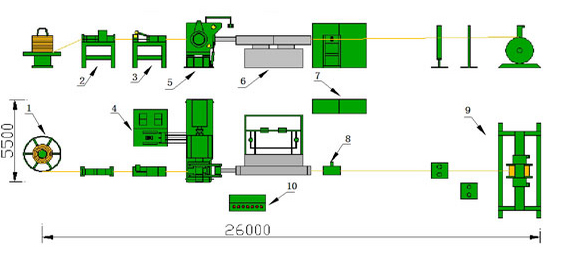

| Copper Alloy Trolley Wire Extrusion Line Layout | |

| 1. Copper Rod Payoff Machine 2. Straightening Unit 3. Cleaning Device 4. Cutting Machine 5. Hydraulic and lubrication system 6. Continuous Extrusion Machine | 7. Cooling and Drying System 8. Electric Control Cabinet 9. Meter Counter 10. Take-up Machine 11. Operation Console |

The continuous rotary extrusion line is especially designed for producing copper alloy trolley wires. The continuous extrusion machine, the key component of the production line, adopts the new die cavity featuring modular construction and high temperature resistance so as to extrude copper alloy products with the tensile strength up to 265N/mm 2 . Through deep processing one more time, the tensile strength can reach 650N/mm 2 .

This range of copper alloy trolley wire production line can effectively improve the constitution of extruded copper alloy wires, making the product structure densified and even. Thus, the requirements for high strength and high conductivity can be fully met. Additionally, our continuous rotary extrusion equipment makes use of the new abutment characterized by great strength and exceptional high temperature resistance. For this reason, this continuous rotary extrusion line is capable of manufacturing copper magnesium trolley wire with the magnesium content being 6‰. It is also ideal for extrusion molding of other types of copper alloy wires.

Technical Specifications

| Main Unit: Continuous Rotary Extrusion Machine | |

| Model | TJ550A |

| Nominal Diameter of Extrusion Wheel | 550 mm |

| Rated Rotation Speed | 8RPM |

| Power of Main Motor | 450kW |

| Feedstock: Alloy Copper Rod | |

| Diameter | Φ20-25mm |

| Diameter Tolerance | ±0.5mm |

| Yield Strength | <=230MPa (Oxygen-free Copper Rod by Upward Casting Technique) |

| Production Line | |

| Average Output | 800-1600kg/h |

| Installed Capacity | 380V, 3 phase, 550KVA |

| Flash Amount | 5-8% |

| Workshop | |

| Minimum Dimension | Length: 40m, Width: 8m, Height: 8m |

| Cooling Water | 80 m³/h, 0.5m² |

| Compressed Air | 0.7 MPa, 2 m³/min |

| Operator | 2 |

| Copper Rod Payoff Machine | one pcs |

| Copper Rod Straightener | one pcs |

| Rod Material Scrubbing and Cleaning System | one set |

| Copper Rod Cutter | one pcs |

| Copper Continuous Extruder | one pcs |

| Cooling and Oxidation Prevention System | one pcs |

| Meter Device | one pcs |

| 2000 Gantry Type Take-up Machine | one set |

| Electrical Control System (with Touch Screen) | one set |

| Hydraulic and Lubricating System | one set |

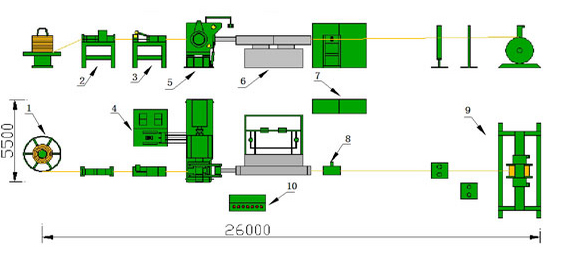

| Copper Busbar Extrusion Line Layout | |

| 1. Payoff Machine 2. Straightening Unit 3. Cutting Machine 4. Continuous Extrusion Machine 5. Cooling and Drying System | 6. Meter Counter 7. Take-up Machine 8. Hydraulic and Lubrication System 9. Electric Control Cabinet 10. Operation Console |

The TJ550 continuous rotary extrusion line is designed to form copper busbars with maximum width of 260mm. By exchanging the extrusion die, the copper extrusion equipment can also be applied to produce copper alloy conductors and other types of copper products with sectional area between 380 and 5000mm2. These extruded busbars are regularly found in power distribution cabinets, electrified railway systems, and more.

Our continuous rotary extrusion line adopts copper rod as feedstock. The maximum rod diameter is 22mm. Available with copper rod payoff machine and extruded busbar take-up machine, our range of continuous rotary extrusion machinery has high efficiency, with maximum output up to 2500kg/h. The touch screen design for its electrical control system ensures optimized operation convenience.

Technical Specifications

| Machine Specifications | |

| Continuous Extrusion Machine Model | TJ550 |

| Power of Main Motor | 450kW |

| Production Capacity | 800~2500 kg/h |

| Flash Amount | ≤5-8% |

| Feedstock Specifications | |

| Copper Rod Diameter | Φ22 mm |

| Diameter Tolerance | ±0.2mm |

| Extruded Product Specifications | |

| Busbar Sectional Area Range | 380~5000mm 2 |

| Max. Busbar Width | 260mm |

| Copper Rod Payoff Machine | 1 pcs |

| Copper Rod Straightener | 1 pcs |

| Copper Rod Cutting Machine | 1 pcs |

| Continuous Rotary Extrusion Equipment | 1 pcs |

| Cooling and Oxidation Prevention System | 1 pcs |

| Meter Counter | 1 pcs |

| Gantry Type Busbar Take-up Machine | 1 set |

| Electrical Control System (with Touch Screen) | 1 set |

| 1. Payoff Machine 2. Straightening Unit 3. Cutting Machine 4. Continuous Extrusion Machine 5. Cooling and Drying System | 6. Meter Counter 7. Take-up Machine 8. Hydraulic and Lubrication System 9. Electric Control Cabinet 10. Operation Console |

Features The TJ500 continuous rotary extrusion line supports producing not only busbar but also other copper alloy conductors such as the copper bar. The extruded products are extensively used as the contact wire for electrical systems, power distribution cabinets, and electric railways. In addition, the continuous rotary extrusion equipment is also optimum for extrusion of copper alloy contact wires, including copper tin, copper silver and copper magnesium alloy with low magnesium content types.

Adopting Φ22 mm oxygen-free copper rod made via the upward casting process as the feedstock, this series of continuous rotary extrusion line is capable of producing copper busbars and profiled bars with width ranging from 170 to 240mm. The touch screen for the electrical control system ensures easy and convenient operation.

Technical Specifications

| Machine Specifications | |

| Copper Extrusion Machine Model | TJ500 |

| Power of Main Motor | 400kW |

| Average Output | 1600 kg/h |

| Flash Amount | ≤5% |

| Feedstock Specifications | |

| Copper Rod Diameter | Φ22 mm |

| Diameter Tolerance | ±0.2mm |

| Extruded Product Specifications | |

| Busbar Sectional Area Range | |

| Max. Busbar Width | 240 mm |

| Copper Rod Payoff Machine | 1 set |

| Copper Rod Straightening Machine | 1 set |

| Copper Rod Cutting Machine | 1 set |

| Copper Continuous Extrusion Equipment | 1 set |

| Cooling and Oxidation Prevention System | 1 set |

| Meter Counter | 1 set |

| Gantry Type Take-up Machine | 1 set |

| Electrical Control System (with Touch Screen) | 1 set |

Features

1. The TJ400 copper busbar continuous rotary extrusion line uses Φ20mm oxygen-free copper rods which can be simply produced using upward casting technique as the feedstock to manufacture high quality oxygen-free copper busbar with a sectional area below 3000mm2.

2. Adopting the innovative online scrapless cutting technique, this range of continuous rotary extrusion machine maximizes the feedstock utilization rate, which helps users cut down production cost.

3. The modular structure of main components and the extrusion die ensures convenient parts replacement, thus minimizing the maintenance cost.

4. The maximum extruded copper product width is up to 170mm, and the average production speed of the continuous rotary extrusion line reaches 1100kg/h.

Applications

This continuous rotary extrusion line is originally designed for copper busbar production. Also, it can be utilized for manufacturing the copper bar, copper rod, and other types of extruded copper products that are widely used in the motors, transformers, and power distribution cabinets.

| Copper Busbar Production Line Layout | |

| 1. Payoff Unit 2. Straightening Unit 3. Cutting Machine 4. Continuous Extrusion Machine 5. Cooling and Drying System | 6. Meter Counter 7. Take-up Unit 8. Hydraulic and Lubrication System 9. Electric Control Cabinet 10. Operation Console |

| Main Functional Unit: Continuous Extrusion Machine | |

| Model | TJ400 |

| Nominal Diameter of Extrusion Wheel | 400mm |

| Rated Rotation Speed | 10 RPM |

| Power of Main Motor | 250 kW |

| Feed Stock: Copper Rod | |

| Diameter | 20 mm |

| Diameter Tolerance | ±0.2mm |

| Yield Strength | 160MPa (Oxygen-free Copper Rod Produced by Upward Casting Process) |

| End Product : Copper Busbar | |

| Sectional Area Range | 150-4500mm² |

| Max. Width | 170mm (or 20-70mm Copper Bar) |

| Entire Production Line | |

| Average Output | 1100kg /h |

| Installed Capacity | 380V, 3 phase, 315KVA |

| Flash Amount | 3-6% |

| Workshop | |

| Minimum Dimension | Length: 30m, Width: 8m, Height: 8m |

| Cooling Water | 80 m³/h (Cooling Tower) |

| Compressed Air | 0.7 MPa, 1 m³/min |

| Operator | 2 |

| Copper Rod Payoff Unit | 1 set |

| Copper Rod Straightening Machine | 1 set |

| Copper Rod Cutting Machine | 1 set |

| Continuous Rotary Extrusion Equipment | 1 set |

| Cooling and Oxidation Prevention System | 1 set |

| Meter Counter | 1 set |

| 1600 Gantry Type Take-up Unit | 1 set |

| Saw Cutting System (Fixed Length: 6m) | 1 set |

| Electrical Control System (with Touch Screen) | 1 set |

| Hydraulic and Lubricating System | 1 set |

1. Due to continuous extrusion technique, the TJ350 copper busbar continuous rotary extrusion line can complete copper busbar extrusion at one time, without the need for edge trimming, acid pickling, etc. Thus, both production process and production period are shortened.

2. The continuous extrusion equipment won't cause production wastes such as the scrap edge of copper busbar, or the residuals in the extrusion barrel. This ensures high raw material utilization rate, and our first pass yield exceeds 95%.

3. Adopting friction force for feedstock heating, our continuous rotary extrusion line for copper busbars eliminates heating and annealing steps. This makes sure the production process is simplified and environmental friendly as well due to lower energy consumption and lower carbon emission.

4. Continuous rotary extrusion machines support producing products with unlimited length. This, coupled with the automatic take-up unit, makes our copper busbar forming machine highly efficient.

5. When the desired busbar width is less than 100mm, our continuous rotary extrusion line offers average productivity up to 800kg/h.

Applications

TJ350 range of continuous rotary extrusion equipment offers an ideal solution to make copper busbars, and other types of copper products by exchanging the extrusion die. The extruded copper products are widely utilized in electric motors, power distribution cabinets, transformers, etc.

| Copper Busbar Production Line Layout | |

| 1. Payoff Machine 2. Straightening Unit 3. Cutting Machine 4. Continuous Extrusion Machine 5. Cooling and Drying System | 6. Meter Counter 7. Take-up machine 8. Hydraulic and Lubrication System 9. Electric Control Cabinet 10. Operation Console |

Technical Specifications

| Main Functional Unit: Continuous Extrusion Machine | |

| Model | 350 |

| Nominal Diameter of Extrusion Wheel | 350 mm |

| Rated Rotation Speed | 12 RPM |

| Power of Main Motor | 200kW |

| Feed Stock (Copper Rod) | |

| Diameter | 16 mm |

| Diameter Tolerance | ±0.2mm |

| Yield Strength | 160MPa (Oxygen-free Copper Rod Produced by Upward Casting Process) |

| End Product : Copper Busbar | |

| Sectional Area Range | 100-600mm² |

| Max. Width | 100mm |

| Standard | Conforms to GB5585.1-85 standard |

| Entire Production Line | |

| Average Output | 400-800kg/h |

| Installed Capacity | 380V, 3 phase, 235KVA |

| Flash Amount | 3-5% |

| Workshop | |

| Minimum Dimension | Length: 30m, Width: 9m, Height: 8 m |

| Cooling Water | 80 m³/h (Cooling Tower) |

| Compressed Air | 0.7 MPa, 1 m³/min |

| Operator | 2 |

| Copper Rod Payoff Machine | 1 set |

| Copper Rod Straightening Machine | 1 set |

| Copper Rod Cutting Machine | 1 set |

| Copper Continuous Extrusion Equipment | 1 set |

| Cooling and Oxidation Prevention System | 1 set |

| Meter Counter | 1 set |

| TU16 Gantry Type Take-up Machine | 1 set |

| Electrical Control System (with Touch Screen) | 1 set |

| Hydraulic and Lubricating System | 1 set |

Contact us if you need more details on Copper Sheet Extrusion Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Copper Bar Extrusion Line、Copper Alloy Trolley Wire. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Copper Wire Extrusion Machine

Premium Related Products

Other Products

Hot Products

Drawing lubricate(wire drawing lubricants)rigid frame cable wire twisting machine500-800DTB Double twist bunching/stranding machinePND 100-630 Flat high speed bobbinPC reels/spools for wire and cable40H(40 heads/lines) annealing and tinning Machine24DB(0.08-0.25)stainless steel wire drawing machine24WDS(0.1-0.6) Horizontal type copper fine wire drawing machine22DS(0.1-0.4) fine wire drawing machine17DS(0.4-1.8) Gear type high speed copper intermediate wire drawing machine14DT(0.25-0.6) Copper fine wire drawing machine with ennealing24DT(0.08-0.25) Copper fine wire drawing machine with ennealing22DT(0.1-0.4)Copper fine wire drawing machine with ennealing17DST(0.4-1.8) Gear high speed copper Drawing Usage wire drawing machine11DST(0.8-2.76) Drawing Usage wire drawing machine13DT RBD (1.2-4.0)450 Copper rod breakdown wire drawing machine with ennealing